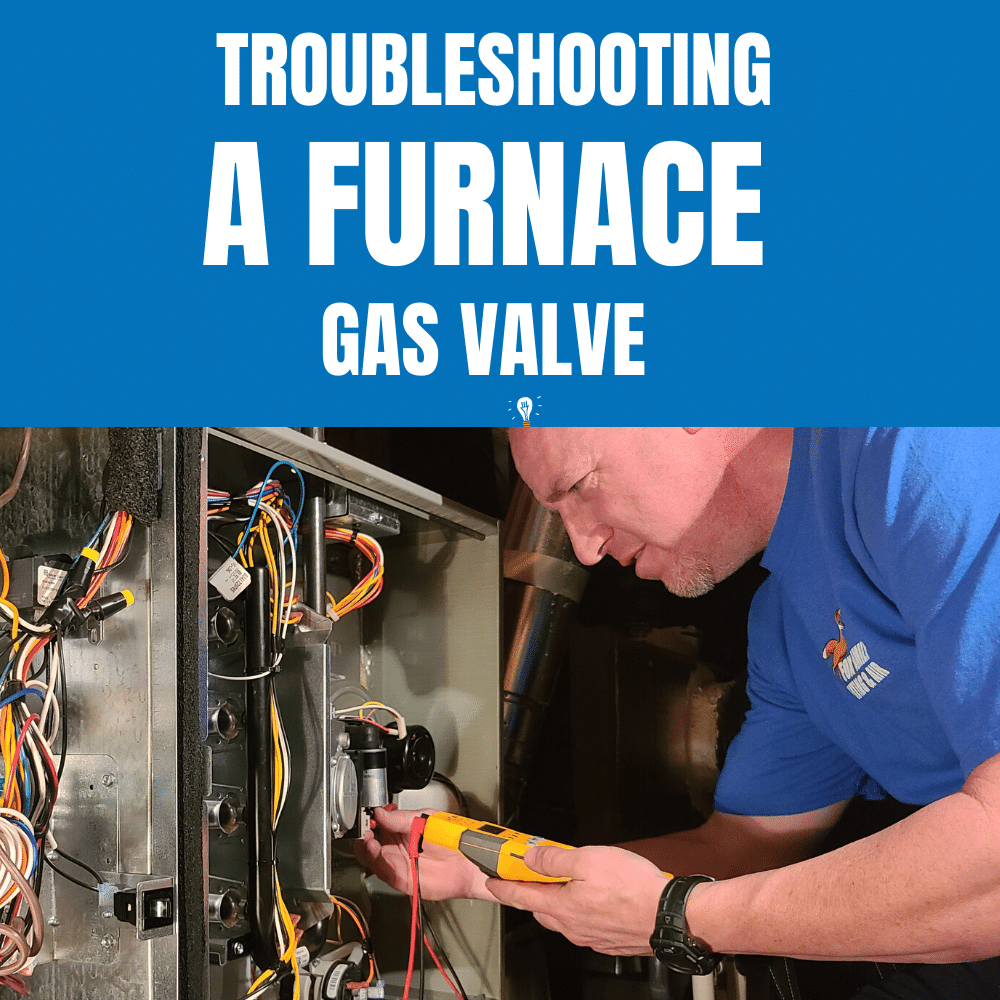

10 Easy Things to Check When Troubleshooting a Furnace Gas Valve

Hey guys, today we’re going to talk about troubleshooting a furnace gas valve. I wanted to expand on our recent gas furnace troubleshooting series by going into each part of a furnace sequence of operation. I’ll describe what the gas valve does and why it’s important. And towards the end, I’ll give you ten things to check when you’re troubleshooting a furnace gas valve. That’s coming up here on Fox Family Heating & Air.

The Furnace Sequence of Events

First, as a technician, you have to know the sequence of events that occurs for a gas furnace to start up properly. It’s straightforward, and you should have this memorized before you can even consider being qualified for troubleshooting a furnace gas valve.

- Power to the furnace control board

- Thermostat signals the call for heat

- Inducer motor kicks on

- Pressure switch proves the inducer operates correctly

- Ignitor activates

- Gas valve energizes

- Flame pours across burners

- Flame sensor proves all burners are lit

- The blower forces air through the ducts

First, the Inducer Motor Starts

When a furnace begins a new cycle, the inducer motor is the first thing you should see kick on. One hundred twenty volts are applied through the wires coming from the control board. This starts the inducer motor for up to 60 seconds before anything else even happens.

Next, a safety device called a pressure switch activates when the diaphragm inside it recognizes the inducer motor’s suction or purging action.

When the “all clear” signal arrives at the control board, high voltage is sent to the ignitor – be it a hot surface ignitor or a spark ignitor. The hot or sparking ignitor stands in the way of the gas that is getting ready to pour over it.

This is Where the Gas Valve Comes Into Play

Modern gas valves typically have a printed circuit board in them that receive a 24-volt signal to activate the valve inside of it. Remember the video I did on printed circuit boards? If not, I’ll attach it below so you can brush up on what they are and the things that can go wrong with them.

This sequence will happen in three stages – and even if one step of this doesn’t perform, each part is still going to do its thing sequentially once the board gives the signal.

So, after the board senses the pressure switch and inducer motor are working:

- 120 volts is given to the ignitor (on some package units, it’s 240 volts.)

- 24 volts is given to the gas valve.

- The flame sensor starts detecting if there is a flame or not.

The ignitor is supposed to come on for a set amount of time: 30 to 60 seconds. (See our video on ignitors for an in-depth explanation of this topic.)

Next, the gas valve opens. The gas coming from the utility company or the propane tank in the back yard is free to flow on to the ignitor. That gas valve is what’s regulating the flow of the gas.

The flame sensor senses whether the flame is correctly burning. At the opposite end of the burner assembly, the flame sensor also stands in the way of the flame. The rod, which should be cleaned annually, by the way, will heat up and send a millivolt signal down to its ceramic base and on to the control board.

Only a certain amount of gas can be allowed to pass through the manifold and on to the burners. The manufacturer of the furnace determines what that will be. It is pretty standard, though—about 3.5″ water columns (wc). The natural gas pressure coming from the street is somewhere around 7″-10″ wc, but the gas valve itself specifically allows that 3.5″ wc onto the burners.

There are some situations and equipment where I’ve been told to bring the outlet pressure down to 3.25″ wc. But I only did it on the advice from the technical support rep from that equipment. Specifically, it was Ruud equipment. The rollouts were getting too hot because the hood covering the flame would trap the heat and make the safety open. Modifying the hood and adjusting the gas pressures were recommended to us, which seemed to fix it.

Furnaces differ, so please check your furnace installation and service guide for your system’s specifics. This is something you don’t want to get wrong.

The gas valve is adjustable. And usually, the installer of the equipment will dial in the outlet pressures on start-up. Because the gas valve manufacturer – Emerson, White-Rodgers, Honeywell, and other valves makers will usually have it pre-set to that 3.5″ wc, some installers forget to do this. We can’t assume the valve is correctly adjusted each time. That’s why you can have issues with your furnace related to your gas valve – because it wasn’t set up right by the installer during its first use.

Troubleshooting a Furnace Gas Valve

If 24 volts is coming from the board to the gas valve terminals and you don’t hear that little clicking noise the internal valve makes, you could have a bad gas valve. To double-check, take the leads off to the gas valve and check there. Got 24 volts? Then something downstream of that 24 volts is not working.

What’s the next thing that’s supposed to be working? The printed circuit board or electric solenoid attached to the gas valve isn’t telling the valve to open, OR that gas valve board IS telling it to open, but the valve is stuck somehow.

If something is wrong with the internal components of the gas valve, it should be replaced. The gas valve cannot be repaired in the field. Only the gas valve manufacturer or someone certified by the gas valve manufacturer can make these repairs.

Some people will literally take a wrench and bang on the gas valve to get it to open up. This is extremely dangerous. Gas is nothing to toy with. If you decide to try this and it kicks on, please replace the gas valve now rather than later.

If we try to fix these ourselves and something goes wrong with the gas valve, and it somehow caught the house on fire, the investigation could come back to the furnace. If they wanted to know who last worked on it and what was done to it, the gas valve manufacturer could claim innocence, and the homeowner’s insurance could deny the customer’s claim. I know that sounds a little drastic, but it could happen. Why put yourself in that situation?

I see people try to fix control boards, ignitors, and such, but we shouldn’t try to fix gas valves ourselves with such a sensitive instrument.

Here are ten things we can check when we think we have a bad gas valve before condemning it:

- Check the wires to the gas valve. Are they cracked or frayed? That could mean a couple of things. You have a REALY old furnace, or something could have scorched the wires—things like that. Replace the wire and continue your diagnostic.

- Check the coil at the gas valve. If you check the coil’s resistance by putting your two-meter leads on each terminal and you get a reading of OL, you have a bad coil. There are more complicated things here but let’s keep this straightforward.

- The gas coming into the valve should be at utility line standards. It’s around 7″-10″ wc for natural gas in my neck of the world. There’s a port on the inlet side to check it.

- You may have plugged burner orifices. A furnace that’s been off all summer can be the victim of a spider spinning a web inside the burner orifices. Now, that’s a tiny spider, I know, but I promise, it happens! Take a small piece of thermostat wire and gently poke inside the holes of the orifices attached to the manifold and try to fire up the system again.

- The flame might be coming on for a few seconds but then shutting off. Is there a dropout of voltage or gas pressure to the gas valve? That’s something to check for sure. And you can do that by putting a “T” fitting in line with the hose to connect to your manometer. Check the inlet and the outlet side to see if the pressure is dropping on either side of the valve.

- Another reason the flame could drop out after only a few seconds of burning is the flame sensor. If the sensor doesn’t detect the flame, the control board will signal the gas valve to shut down.

- If the flame does anything but shoot directly into the hollow metal heat exchanger, a safety can trip. One safety trip is the rollout switch. Sometimes you’ll get a little part of the flame that drifts off to the left or right, sending the switch off. That doesn’t mean you should remove the switch. It means you need to fix the problem. Clean the end of the burner assembly nearest the heat exchanger. Rust will sometimes build up on the crossover channels. Use a wire brush to clean and see if that solves it. Then place the burner correctly into the channel.

- The other safety trip that can cause the system to cut the gas off to the valve is the high limit switch. If the furnace runs for a few minutes, then shuts off, something could be causing the inside of the furnace to get too hot. The first thing I would check is to see is if the evaporator coil is dirty. I have a great video that shows what a dirty evaporator coil looks like and what it takes to clean it.

- The other reason the high limit could open is the blower motor speed could be set too low. Check your installation guide as a reference for where the settings should be.

- Check the ductwork too. These last three have all dealt with airflow. If the return duct is crushed, then we’ll have low airflow again. Visually check the return duct and feel around it if it looks questionable. If the duct is not perfectly round, then this could be the problem. The furnace is suffocating.

What else should folks check when troubleshooting a furnace gas valve? Leave me a comment down below to share your expertise.

When you’re installing the new gas valve, there are few things to keep in mind. It’s a like-for-like change out, but gas leaks are a serious issue, so make sure to use some pipe dope or pipe tape to seal the fitting.

Also, don’t bend the manifold when you’re trying to remove the gas valve or put the new one back on. Use two wrenches to get a proper hold on the manifold and the gas valve.

I strongly recommend not over-tightening the gas valve to the manifold. You could bend the manifold, but also remember, someone might have to get that thing off someday, and you’d be creating a challenging situation for a tech that has to come out and service it in a few months. Some guys get a little over the top and really crank down on it. Not necessary.

Check for gas leaks with an electronic gas sniffer or soap bubbles. This will assure you the fittings are snug and leak-free. And don’t forget to check the outlet side when the gas valve is on. It doesn’t help when the valve is off because no gas is flowing through it.

If it’s a natural gas set-up, the spring that comes inside the valve will already be the right one. If you’re using LP gas, you’ll need to make sure you put the right spring in it. It’ll come in the box. Check the manifold orifices to ensure they are the right ones for LP too. And put the sticker on the gas valve that says LP. This will help future HVAC technicians when they service the furnace.

And lastly, check the gas pressure on the new valve after you’ve replaced it. I can’t say it enough. It’s simple to do with the right tools, don’t just change the valve and not check the pressures.

When it comes to troubleshooting a furnace gas valve, there’s also a setting for low fire on two-stage units that needs to be checked.

If the gas pressure is too low, your furnace’s efficiency will go down. More condensation than usual will build up because the air in the air-fuel mixture will be too high. The condensation can cause corrosion, possibly creating the need for a heat exchanger replacement in the future.

High gas pressure can be just as bad for your furnace because it dramatically increases the furnace’s overheating risk. When this happens, high limit switches will start opening, causing intermittent operation. It can also crack your heat exchanger since it’s only rated to handle a certain amount of heat. And cracked heat exchangers can introduce the spent gasses inside the heat exchanger to be carried along with the heat blowing into the house.

So, to recap. When a furnace begins a new cycle, the inducer motor is the first thing you should see kick on. A safety device called a pressure switch activates when the diaphragm inside it recognizes the suction or purging action of the inducer motor. Next, the three parts of the ignition sequence begin. The ignitor kicks on, the gas valve opens, and the flame sensor senses that the flame exists. If this all goes well, you have heat blowing into the house about a minute later when the blower kicks on.

What else should folks check when troubleshooting a furnace gas valve? Leave me a comment down below to share your expertise. Thanks so much for stopping by, and we’ll see you at the next blog post.