Condenser fan motors come in a couple of forms. PSC style and ECM style. PSC motors are easily identified by the run capacitor that comes inside the service panel with them. ECM motors are electronically commutated motors run on their own power. Today we’re talking about the PSC condenser fan motor which you’ll find on a lot of the basic 10 to 14 SEER single-stage systems out there.

There are only a few things that can go wrong with your typical PSC motor. Voltage from the panel isn’t sufficient, the contactor is bad, the capacitor is bad, or damaged parts inside the condenser fan motor.

Why Is The AC Making A High Pitched Noise?

I’ve gotten this call before. The customer says the outdoor unit is making a very pitched noise. Louder than they’ve ever heard! When you get to the house and turn on the AC, you walk up on the outdoor AC unit and find that the compressor is pumping the refrigerant, but the fan on top is not spinning.

What’s happening here is the condenser fan blade isn’t spinning which normally removes the heat from the outdoor unit. If it doesn’t, the compressor will overheat and shut down, but not before putting up a screaming hissy-fit. After that, the internal overload switch on the compressor opens. It takes about 45 minutes or so to cool back down, and then retry running again. Heats up, shuts down, cools off, restarts, and over and over.

In this case, you likely have good voltage to the system but just to be sure make sure you have about 240 volts to the load side of the contactor while it’s running. This lets you know the line voltage is good and the contactor is good in one quick test with your multimeter.

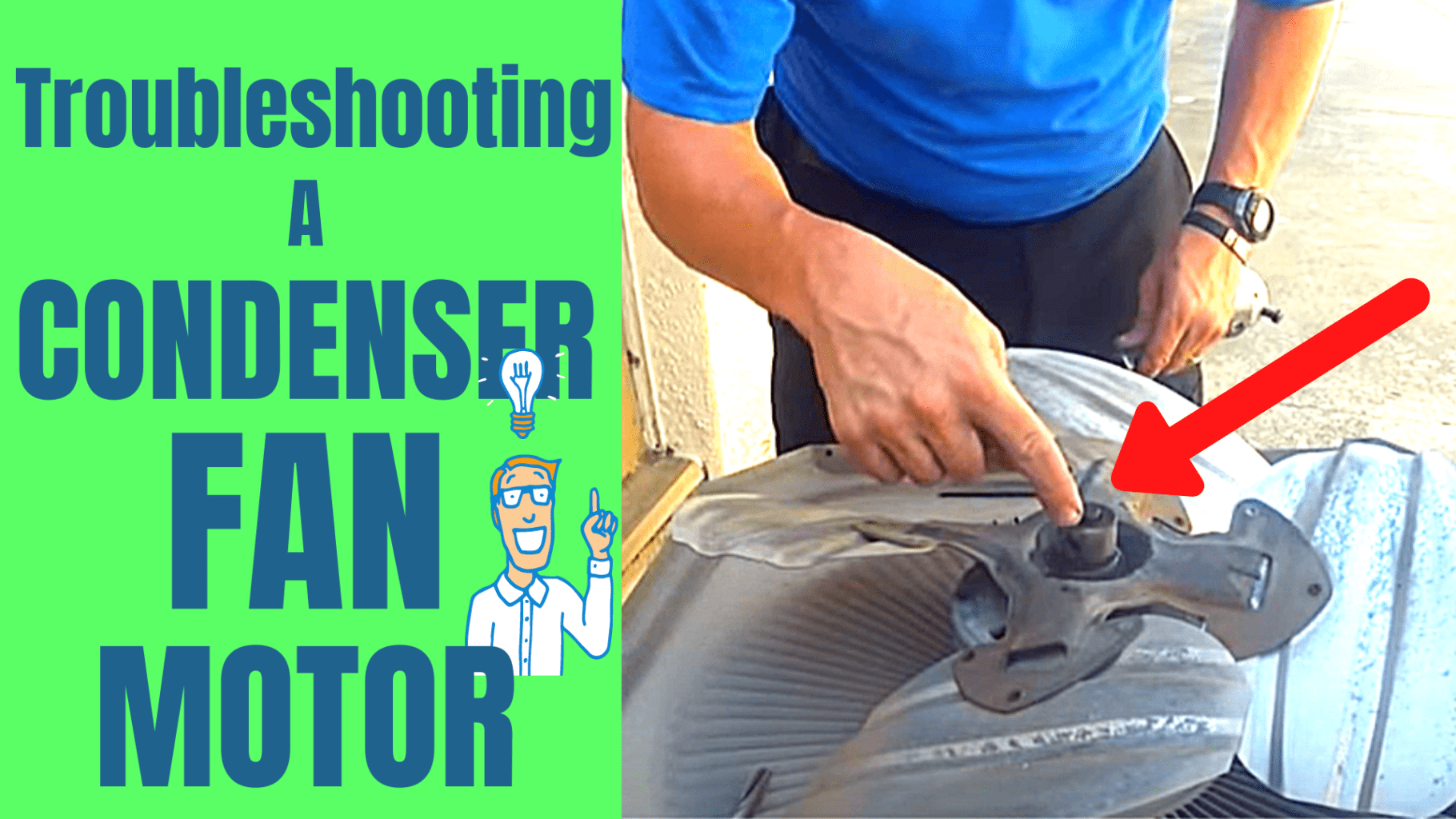

You only have so much time to do this before the compressor shuts down, but next, I usually take a stick or something and try spinning the fan blade with it. If the fan starts spinning after giving it a little nudge, I’d check the capacitor next. That capacitor is what helps it start and run efficiently.

If the capacitor checks out good, then you know you have proper voltage getting to the motor, so the condenser fan motor is bad.

If the fan blade doesn’t keep spinning after you nudge it, the capacitor could be good, but still, check it. If it’s good, the condenser fan motor is bad.

Checking The Condenser Fan

I’ve seen this happen when a big windstorm hit an area recently and knocked some branches down into the top of the AC. The shroud on top usually does a great job of protecting the fan blade, but in this instance, a stick wedged itself in there and caused the motor to burn out.

Another reason this can happen, especially on universal replacements is the inside of the motor got wet. These motors come with rubber plugs sometimes. These plugs have to be placed on the top side of a downward mounted fan, and in the bottom of an upward facing motor. The ports on the opposite sides should remain open, so that any moisture that does get into it, can drain out. Happens all the time!

I would say check the fan motor for a short to ground, but the main breaker or service disconnect fuses would have usually tripped by now. So let’s check the motor windings first to see if we have an open or damaged winding.

Take the wires off the contactor and the capacitor that leads to the fan motor. Refer to your wiring diagram that comes with the AC and check your ohms (resistance) between Common (Purple or C on the capacitor) and Start (Usually Brown but was attached to Fan on the capacitor.) You should read a fairly low amount of resistance here. If you read OL on your meter, then you have an open Start winding

Common and Run (Black, or the only wire that’s coming from the contactor to the fan motor.) You’ll likely measure a lower amount of resistance here. If it’s OL, then you have an open Run winding.

If you have an OL on both of the motor’s windings, the motor’s internal overload switch could be open. If you allow time for it to cool down, and it still wont run, replace the condenser fan motor.

Just in case you do have good windings, let’s double check to make sure the motor isn’t shorted to ground. You can check with your ohm meter, but I usually just use the continuity setting on my meter. Check between the frame of the motor and each winding. Common, Start, and Run. Make sure you’re not using a painted surface for the frame. You want to use a metallic base for this test.

If you have continuity between any of these and the frame of the motor, replace the condenser fan motor.

Well, I hope this helps you troubleshoot your next condenser fan motor. This is one of the easier components to check.

If this is your first time watching our channel, please click subscribe down here on the bottom right. And if you click that little bell next to it, you’ll be notified of all our videos as they come out.

Thanks so much for reading and we’ll see you on the next blog.

Fox Family Heating & Air serves Sacramento, Rancho Cordova, and all of Northern California. If you’re looking to schedule HVAC service in these areas, give us a call!