Have you been told that duct board used for an air plenum for your HVAC system is dangerous to your health? That flakes of insulation are falling off every day and entering the air stream that you breathe in your house? Does Fiberglass duct board cause cancer? How long does duct board last before I need to change it?

Boy, I’ll tell you what. Every time I dive into a blog, I like to use my personal experience as an HVAC tech and relate it to common questions customers ask me. But I love getting into what the real facts are. I like to talk to people in the industry who make the product and contemplate what the EPA, ACCA, or ASHRAE has to say about it too.

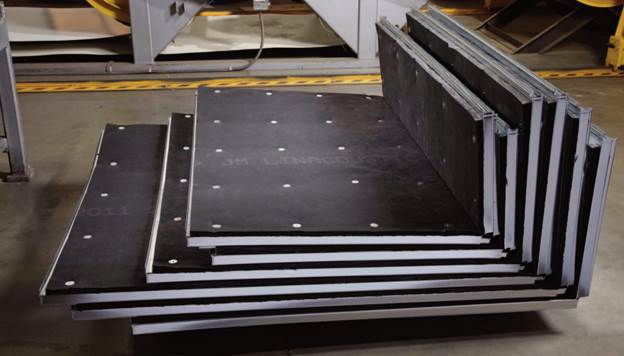

The type of duct board I find in a lot of systems is similar to Mat-Faced Micro Aire Fibrous Duct Board.

We see duct board so much because neighborhoods built around 2000 have gone through their share of service calls. Several of those homes have changed their AC system out completely. But the plenums used for those systems have typically been duct board plenums.

But even if those homes had sheet metal plenums. They’d still have fibrous duct insulation inside them? If they didn’t, the metal plenum or distribution box would get hot in the heating season and start to sweat in the cooling season.

Guess how many parts of your HVAC system have this fibrous glass insulation as part of its construction. At the very least, three, not one. You have the furnace, the evaporator coil, and the air plenum.

I don’t understand why HVAC salesmen tell folks who are buying a new system that they should have a new plenum installed, specifically to prevent the use of duct board. Are they just trying to pad the commission they get after selling you a system? Because again, there’s no getting around it. All manufacturers use it in their equipment.

Super-salesy type companies create “fiber phobia” in a customer’s mind, either because they heard it from their trainer or just randomly finding things on the internet to scare you into spending more money.

Here’s a sample of opinions that I’ve read from sooooo many HVAC and green energy websites:

“After the primary seal has fully deteriorated, it allows raw fiberglass fibers to be exposed to the airstream. Turbulent airstreams wick the raw fiberglass fibers through the ventilation system, creating additional deposits within HVAC components and exposing building occupants to raw fiberglass fibers.”

Companies also show those terrible pictures of mold and dust build-up inside ducts to convince you to change your ducts or clean them. I see mold and spores in just as many vinyl-lined ducts as I see in duct board. If the system is regularly maintained, like something as simple as changing your air filter every 90 days, how will dirt and debris find their way into the duct system anyway?

But, let’s look at some facts:

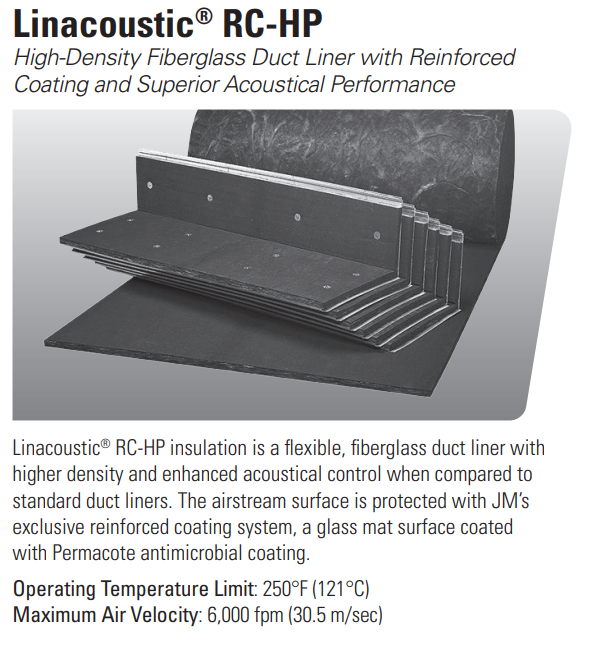

Manufacturers like Johns Manville and Owens Corning test their products. They use an isokinetic sampling method as well as long-duration testing. The manufacturers rate their product for use up to 6000 ft per minute—way more than your typical residential HVAC system.

To pass the test on complying with UL-181 Section 17, the materials used in the fabrication of air ducts “shall not break away, flake off, or show evidence of delamination or continued erosion when air is passed through typical sections at a velocity of two-and-a-half times the manufacturers rated velocity.”

I found another snippet of research on the Johns Manville website: The potential for any shedding of glass fibers from the duct’s surface was evaluated at the maximum recommended velocity of 6000 fpm. Testing was conducted using an air duct fabricated into an L shape as described in Sections 17.2-17.3 of the UL 181 procedure.

Sampling the airstream at the same air velocity as the test velocity conducted near the outlet of the duct and examined by Phase Contrast Microscopy following NIOSH Method #7400 demonstrated no detectable glass fibers in the seven-hour test. The sampling detection limit for this test is 0.01 fiber/cc of air.

Test samples contained fewer fibers than values reported for outdoor ambient air. Reviewing several major studies, the World Health Organization’s International Program on Chemical Safety (1988) concluded: “The contribution of fibrous-glass-lined air transmission systems to the fiber content of indoor air is insignificant.”

Complying with ASTM-C1071, the Standard Specification for Fibrous Glass Duct Lining Insulation, The following test methods have to be performed: corrosiveness; water vapor sorption; fungi resistance; temperature resistance; erosion resistance; odor emission; surface burning characteristics; apparent thermal conductivity; sound absorption coefficients; bacteria resistance; and combustion characteristics.

With duct board being so thoroughly tested, that should prove to you a few things:

- There is no “causal association between cancer or non-malignant pulmonary disease and human exposure to glass fibers.”

- That biosoluble glass wool fibers are thin enough that fibers disappear from the lung at the same rate as dust in the air we breathe every day.

- That levels of respirable glass fibers in most settings are less than 1 fiber per centimeters cube,

- And that airborne levels in insulated buildings are not significantly different than levels outside or in uninsulated buildings.

The following bodies, which are well-known industry names, can be used as references when making your assessment of whether duct board plenums are dangerous:

- NAIMA – North American Insulation Manufacturers Association

- ASHRAE – American Society of Heating, Refrigeration, and Air-Conditioning Engineers

- ASTM – American Society for Testing and Materials

- EPA – Environmental Protection Agency

- NFPA – National Fire Protection Agency

- SMACNA – Sheet Metal & Air Conditioning Contractors’ National Association

- ICC – International Code Council, Inc.

- AIA – American Institute of Architects

- AIHA – American Industrial Hygiene Association

- AMA – American Medical Association

Don’t Homeowners Replace Their Ducts Anyways?

Does ductwork need to be changed out at some point in the life cycle of your home? Yes, most likely – whether it be flexible vinyl ducting or duct board. If for no other reason than when you move into a recently purchased home. I personally don’t want to be breathing the air, dead skin, hair, mites, and other disgusting deposits that may have made it into the ductwork from the last people who lived there.

Having provided the service myself for customers, I don’t believe duct cleaning works as well as people think. It might knock the dust off, but it doesn’t disinfect or make it like new.

Home inspectors take a look at the exterior of ducts and determine the shape they are in by a brief glance in the attic. But they don’t look inside them, so the ducts will pass the inspection. But for me, as a new home buyer, I’d want to change them out.

Another reason you change out ductwork, regardless of the type of material it’s made of, is the vapor barrier surrounding the ducts. Is it shredded or falling apart? Does your home have hot or cold spots? Uneven airflow? Smashed ducts from a serviceman who needed access to the space? These are other reasons to change or upgrade your ducting.

Conclusion:

Regardless, today I wanted to clear the air about yet another way HVAC companies send their guys out into the field with bad information. I couldn’t find any facts why using duct board would be a poor choice or that you should change your duct board plenum because it flakes off and enters your air stream. They were all fluff written by blog writers or companies talking about stuff they don’t REALLY know about.

My company doesn’t install duct board when we change duct systems out. We typically use flexible ductwork. But we do install plenums that are lined with the fiberglass we’ve discussed today. And remember, it’s already in your new HVAC system anyways, for insulation and sound attenuation. So, this hasn’t been a sales presentation. I just like to know the facts, and I thought you would too. That’s why we’ve cited specific standards made by the industry’s major players and told you their observations.

So hopefully, this has helped with any questions you have about fibrous glass duct board.

If this is your first time watching our channel, please click subscribe down below here on the right. And if you click that little bell next to it, you’ll be notified of all of our videos as they come out.

Thanks so much for watching, and we’ll see you on the next video!